Meet Our Engineering Intern

Rebecca Geier

Rebecca Geier

We were thrilled to have our first engineering intern start with ChemVM this spring. I asked Sean to take a few minutes to introduce himself, what drew him to engineering and what he's contributing at ChemVM.

RG: Tell us a little about yourself - where are you from, where do you go to school and why you took the year off with COVID?

SS: My name is Sean Scadden, and I am currently an intern at ChemVM. I am originally from Oregon but have recently moved to Utah. I will be starting my senior year at Stevens Institute of Technology. I would have been graduating this May of 2021; however, I took the year off. I decided that instead of earning an online degree I would use this year to further develop and learn more skills by interning at ChemVM. To me, this plan made the most sense as I have learned far more about the chemical engineering industry and business side than I would have in Zoom classes.

RG: What specific area of engineering are you studying and why did you pick it?

SS: At Stevens Institute of Technology, I am majoring in Chemical Engineering and minoring in Sustainability (Green Engineering). My interest in engineering stems from my childhood. I would take apart household items because I was curious to learn how things work. Eventually when chemistry classes became available for me, I gravitated towards that subject. This continued and led me to the path of chemical engineering.

RG: What have been your favorite classes and most interesting projects in school so far?

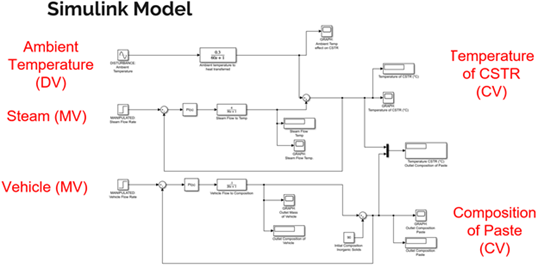

SS: One of my favorite classes at Stevens was Process Control, Modeling and Simulation. This course established the fundamentals of model development, parameter estimation, analysis of process dynamics and process control in chemical engineering. The most interesting aspect of this class was the final project, which was to model the process for a specific patent. In order to do this, I used MATLAB Simulink software to model a feedback control for the process with ambient temperature being the disturbance variable, the control variables being the outlet composition and the temperature of the reactor, and the manipulated variables being material flow rate and the flow rate of the steam. The image below shows the final Simulink model.

RG: What are your main responsibilities at ChemVM and what are the highlights of work so far?

SS: My primary responsibility for ChemVM is to profile potential suppliers. This consists of researching publicly available information on the web about a chemical supplier and documenting the data in our chemical supplier database. This backend data mining work to profile the chemical manufacturing capabilities of each supplier powers the ChemVM matching database to more accurately match customer projects with the perfect-fit chemical service provider. The highlight of my work so far was finding a supplier that was the ideal fit for a project a customer entered in the platform. It was super exciting to see my supplier profiling work be helpful. I am currently working on a chemical reactions video project, and I am excited to see it completed and launched. Another project I am hoping to get more involved in is streamlining our data management for suppliers so we can capture even more capabilities of each unique service provider.

RG: As an up-and-coming ChemE representing the next generation of business and technical leaders in the chemical industry, what is your perspective on the industry's adoption of digital platforms like ChemVM?

SS: As a young chemical engineer, I view the industry's adoption to digital platforms as extremely advantageous for both chemical service providers and customers. For customers, it speeds up the searching/contracting phase of projects, not to mention ChemVM can find service providers who help even in the R&D phase. This helps increase project velocity by reducing one of the most time stringent steps. For chemical service providers a digital platform allows them to truly market and distinguish who they are as a company and what their capabilities are. This allows for companies to hone in on their service capabilities and not take projects outside their skillset due to inability to find projects. Overall digital platforms such as ChemVM create a win-win scenario that will be a crucial part in the future to increase project velocity, improve customer experience and reduce wasted searching time. In this 2017 article by Deloitte, chemical industry analysts outlined the benefits of digital transformation, including both improved customer interactions and asset utilization:

"Watch out for digital disruptions and leverage digital in newer ways: Chemicals companies should not only look at new areas in which digital can add the most value (e.g., customer engagement), but also how they can further strengthen their core businesses using digital (e.g., asset utilization). They also should pay attention to digital disruptions happening in their end-markets and how those can impact their businesses."

I am proud to be a part of a company with an incredible vision for the future.

RG: What do you do for fun in your free time?

SS: Outside of ChemVM, I enjoy a lot of outdoor activities - being in Utah there is plenty to do. Specifically, I love fly fishing and skiing. Usually, I play lacrosse in the spring for my school, but for now I am just practicing on my own but I’m super excited for when I return.